Warning

I am not a mechanic or a representative of any motorcycle or tool manufacturer or anything else official. This page is only my notes on doing this procedure myself. Although I believe what I have documented here is correct, I make no promises and you do this at your own risk.

Objective

Valve clearance adjustment is required at regular intervals. My manual specifies checking every 12,000 Km, and I’ve never checked without discovering adjustment needed. For me, it’s the most technically challenging thing I’ve done. For that same reason, it’s the most satisfying, and the most money-saving.

This job takes a long time — allow 8 to 12 hours, with a trip to the shop at the halfway point.

Perhaps that needs clarification. This job took me 8 to 12 hours and, if you have never done this kind of thing before, it will probably take you that long. Maybe a little less, because I was pausing to take pictures. No doubt experienced mechanics can do it in a hour, with one hand.

For the techies, the 2000 ZX-6R uses shim-under-tappet valve clearances.

Required

Tools Required

- Rear stand (recommended)

- Factory service manual (there are too many critical specifications to go without, and I can’t promise yours will be the same as mine. Get the manual, and use my description here just to help you understand the steps).

- Phillips screwdrivers

- Hex wrenches

- Metric sockets.

- Torque wrench

- Feeler gauges in the appropriate range. As much graduation as you can get in the 0.1mm — 0.3mm range is what you are looking for.

- Micrometer (not actually required; in theory you can do the calculations with the shim-type code marked on the shim, and the shim substitution table in your service manual. I prefer to measure and do the subtraction myself.)

Supplies Required

- Replacement shims (but you need to do half the job before you know how many or what sizes)

- Or, you can pre-purchase a shim kit which provides several each of most sizes. Then, chances are you won’t have to go to the shop for shims. You can keep your old shims too, possibly using them later when that size comes up as what you need.

- Pickup coil cover gasket

- Possibly a valve cover gasket (may be able to reuse old one)

- RTV silicone sealant

- Blue LocTite

- Coolant

- Distilled water

Difficulties & Warnings

Some difficulties could be:

- It takes a long time because of the number of steps and the amount of disassembly required. Also, because you must do a bunch of work before you know the details of a part (replacement shims) you need, it requires a trip to the motorcycle shop mid-job, so you probably are forced to take at least two days to do it.

- Also, check if your bike shop keeps shims in stock. If they have to order them for you, your bike will be out of commission while you await the order. Usually they have a complete set in the service department and will, if you ask politely, sell you stock from their service set. Some shops will also take your old shims in trade.

- Lots of opportunities to drop small parts into dark corners

- Correct torque of engine bolts is critical

- Correct re-installation and alignment of cam chain is critical

Procedure

Putting the bike on a rear stand makes this job much easier by leveling the bike and holding it steady.

First:

- Remove the seats

- Remove the gas tank

- Remove the air filter assembly

- Remove the carburetor assembly

- Drain the coolant

Then:

Remove Pickup Coil Cover

Next you need to remove the “pickup coil cover”. It’s on the lower right side of the bike, in front of the transmission.

Remove the cover bolts. The topmost will be extra tight, as it has Loctite in it.

When you take the cover off, a small amount of oil will spill out, so have a pan underneath to catch it.

I’ve never removed this cover without destroying the gasket — it comes off in pieces.

So, I use a razor blade scraper to carefully clean the old gasket off both the cover edges and the unit edges.

Then I use air to blow the bits of gasket out of the cover. Don’t try to blow it out of the chamber on the bike — oil will fly out. Just use a rag to clean out the area.

Remove engine top-end connections

Now you remove all the various fiddly bits that are in the way of taking the top off the engine.

Label and remove the main vacuum hose.

Label the spark plug coils 1-4 with a silver Sharpie or masking tape, then disconnect the wiring harness that feeds the spark plugs, and pull out the stick coils that connect to the plugs.

As part of removing the wiring harness, you must disconnect a ground lug that is fastened to one of the vacuum valve covers. Remember where this was.

Now remove the Engine Side Cover. It’s the black cast aluminum cover under the radiator hose.

Remove the mounting bolts and lift the cover away.

Dismount and Lower Radiator

You’ve already drained the radiator. Now remove the mounting bolts, on the right,

Just let the radiator sag down toward the ground, and put a support of some kind under it to hold it securely.

Remove valve cover

Having cleared the clutter away, you can now remove the valve cover bolts.

Tug sharply on the valve cover to break the seal along the gasket,

and lift the cover off. It slides out toward the front of the bike, and takes a bit of twisting and turning to get it out.

Actually, it takes a lot of twisting and turning. You will be sure it cannot be removed this way then, suddenly, you will turn it to a slightly different angle and it will lift away like it was never a problem. It’s quite magical.

Here’s the cover loose, sitting on the frame of the bike.

Check Valve Clearances

Valve clearances are measured by sliding a measuring feeler under the cam lobes on the camshaft. The bike has 16 such lobes — 4 per cylinder (2 input valves and 2 exhaust valves per cylinder). Here is one of the input lobes (the side set of cams toward the rear of the bike is the inputs).

And, toward the front of the bike, viewed from under the frame, are the exhaust lobes.

The lobes make contact with, and press down on, highly polished metal cylinders called tappets and these, in turn, press on the valves themselves.

Note that all the lobes are not pointed in the same direction. At any given moment some valves are closed and others are open. We need to ensure we are checking the gap on valves that are in a specific opening state,

namely when the respective cylinder is in “top dead centre” position. The lobes at the extreme left here are in this position, ready to check. The point of the lobe is pointing sideways, at right angles to the tappet, completely clear of it, and the point is facing out, away from the centre of the engine. (There is another position where the lobe is sideways but is pointing in, toward the centre of the engine. That’s not the right one — you want it pointing outward.)

The big bolt on the pickup coil, which you uncovered a while ago, is used to rotate the engine, and therefore the cams, for adjustment.

Rotate with a socket. A line is engraved on the rotating plate, and another on the housing. When these are lined up, some cylinder will be at the appropriate position for checking.

You rotate a set of cams to the correct position and check the clearances by sliding feeler gauges into the gap between the lobe and the tappet, looking for the largest ones that will fit with only slight resistance. In this photo we’re checking the rightmost cylinder.

Then, rotate the camshaft to bring the next pair of lobes (2nd from the right here) into position.

The manual suggests an order of checking valves that minimizes the amount of manual rotation. I feel more comfortable doing them in order, so I visually get a set close, then use the registration marks, then repeat on the next set. I tend to work right-to-left since I’m standing on the right side of the bike.

Use the alignment of the registration marks to ensure the positioning is perfect.

Measure all 16 lobes this way.

Keep careful notes: for each cylinder, write down the clearances on both input valves and both output valves. It’s easy to lose track here.

Now What?

If all your clearances are in range, you’re done. If not, you’ll need to adjust them.

My service manual says the input cams should have a clearance of 0.11mm — 0.19 mm and the exhaust cams should have a clearance of 0.22mm — 0.31mm. In the session being photographed here, three of my clearances are not in the appropriate range, so we will adjust the clearances by replacing the shims that set them.

Remove Shims Requiring Adjustment

To remove the shims, you must take the camshaft cover off and remove the camshafts. You’ll also have to remove, and later reset, the cam chain tensioner.

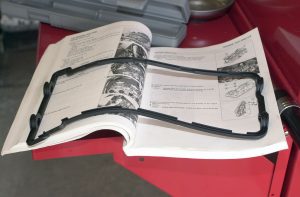

First, peel out the rubber valve cover gasket. These are reusable if you’re careful. I have reused a few successfully, but also damaged one once and had to replace it after doing a lot of re-assembly. I now prefer to just replace them.

Locate the cam chain tensioner on the rear-facing side of the engine.

Remove it in two pieces — centre bolt first, then outer two bolts and housing. Warning: once you have so much as loosened these bolts, you cannot reinstall this part without resetting it (below).

Remove 20 bolts from the cam shaft cover.

Lift the cover off, exposing the cam shafts.

Lift the shafts out and set them aside.

Now we can see into the engine to the tappets, the hard smooth metal cylinders that sit on top of the valves, and that are pressed on by the camshaft lobes.

These highly polished metal cylinders are the tappets, and each one has a shim under it.

Pick one of the valves that needed adjustment,

and gently lift the tappet out.

They’re hollow. Usually the shim is stuck to the underside, inside.

But they can remain behind — here the shim is still sitting on the valve (yellow circle).

Carefully retrieve the shim.

Calculate Sizes and Get Replacement Shims

In theory, you can calculate the replacement shim using a table in the service manual and a code stamped on the shim. On my bike, the code is worn by the engine motion and is difficult to read, so I prefer to do the calculation myself. It’s just a question of measuring and subtracting, like this:

We measure the shim carefully with a metric micrometer. In this case it is 2.892 mm (shims come in .05mm increments, so it was probably 2.90 originally).

This valve’s clearance measured 0.18 mm, but the book says it should be 0.22. So we need the gap to be bigger by 0.22 — 0.18 = 0.04 mm. So we need a shim that is smaller by this amount. 2.892 — 0.04 = 2.852mm, so we’ll need to replace this shim with a 2.85mm shim.

After calculating all 3, off to the bike shop to buy 3 shims of the appropriate new measurement.

Checking the new shim with the micrometer shows it is (close to) the desired 2.85mm.

Shims are slightly magnetized so they will stick to the inside surface of that tappet. Put them in and reinstall the tappets, doing one at a time so the tappets don’t get mixed.

Reinstall Camshafts and Cam Chain

Now you need to re-install the camshafts so you can re-check the clearances.The shafts are marked for “input” and “exhaust” sides — make sure they don’t get mixed.

They’ll sit in the engine like this (though not touching) — input on the left and exhaust on the right.

The next critical job is to ensure that when the cam shafts go in they are rotated to exactly the right position for the current state of the engine pistons. There are registration marks engraved in the faces to support this. I put a white felt pen line on the marks to make them easier to see.

Making sure the engine is still rotated to “top dead centre” (by checking the pickup coil registration marks), put the exhaust-side camshaft in so the registration marks line up exactly with the surface of the engine housing.

Note: Ensure the chain going down from the exhaust-side camshaft into the engine is tight. i.e. any slack in the chain is on the left, input side, not the right side.

The input-side shaft is positioned relative to the exhaust-side shaft by counting a specific number of links on the cam chain.

On my engine, one rotates the input-side camshaft so that there are exactly 28 chain rivets between the registration mark on the exhaust camshaft and the registration mark on the input camshaft. i.e. 30 including the rivets at the registration marks. i.e. if you number the rivet at the first registration mark #1, then rivet #30 is at the other registration mark. I pre-marked the rivet with white felt pen to make this easier.

Now to reinstall the camshaft cover.

It doesn’t fit down snugly when loose, because the turned-down camshaft lobes are holding the camshaft up.

So we have to put the camshaft cover bolts in — all 20 of them —

and slowly and carefully snug them all up, moving around the whole cover until they are all evenly tight. They interact, so don’t tighten any one bolt all the way all at once — move around in a pattern.

Two of the mounting bolts also hold the cam chain cover in place.

Tighten all the cover bolts firmly but not excessively tight,

then use a torque wrench to bring them to the exact torque specified in the manual. Mine says 12 Nm (104 in-lb). This torque value is critical — use a torque wrench.

Reset and Reinstall Cam Chain Tensioner

This is how the cam chain tensioner looked when we removed it. We need to reset that plunger under my thumb.

We release a ratchet mechanism and push the plunger all the way in,

then back it out 5 clicks.

Now insert the tensioner back in its hole.

Tighten down the two outer mounting bolts,

then insert the big central bolt and tighten it.

Re-check Valve Clearances

Now, we rotate the engine through 2 or 3 rotations using the rotation bolt, then we re-check the clearances on the valves we adjusted — sure enough, they are all now in spec.

Reinstall Valve Cover

I like to use a new valve cover gasket, although old undamaged ones can be safely reused.

(I had to take the engine apart a second time on another bike when the gasket leaked, so I went through a period where I always used a new gasket; eventually I regained my courage and started carefully re-using old gaskets, with no problem. The leak wasn’t because the gasket was old, it was because I didn’t reinstall it carefully enough.)

4 recesses milled into the cylinder head correspond to 4 bulges in the gasket. Here are the left two,

and here is one of the two on the right. (The other is hidden by the wire bundle in this photo.)

Those recesses are supposed to be sealed with RTV silicone sealant.

(By the way, I’d love to know the purpose of these recesses. The only things I can imagine is either that they create some additional space for rubber to expand or contract when the hot engine changes size, or that they are some kind of “blow out” hole that releases over-pressure during a disaster. But I’m just guessing. Anyone know?)

I find putting the sealant into the recess (as the book suggests) difficult,

so I prefer to put it on the gasket and spread it evenly. (I put a thin layer around the entire gasket, not just in the recesses.)

Install the gasket and take lots of time to check that it is properly seated all around. It seems particularly prone to coming out of place around the cam chain.

Then, we fight with the valve cover, working it in from the front, reminding ourselves that we took it out only a few hours ago, so there must be some way to fit it back through that gap,

until we finally manage to fit it over the cam chain,

and we make sure the cover is firmly seated on the gasket. We have almost certainly knocked the gasket out of position while struggling with the valve cover, so re-check it carefully, all the way around.

Put the cylinder head bolts, with their special plug washers, back in place,

and use a torque wrench because their torque is critical. My manual specifies 9.8 N-m (87 in-lb) for these.

Put the engine side cover back in place too.

Reinstall Pickup Coil Cover

The pickup coil cover goes back here.

Having destroyed the old gasket, we’ll put a new one on.

The manual calls for some RTV silicone at two positions (the two places where the old gasket stuck and had to be scraped off, in fact).

We spread some carefully in the specified spots, being very sure not to get any on the pickup coil mechanism, and re-install the gasket and cover. Again, the torque of the cover bolts is very important, so use a torque wrench. My manual says 11 N-m (95 in-lb). The topmost bolt also calls for LocTite.

Check Air Suction Valves

While putting the air suction valve cover back on, it occurs to me that I should check those suction valves (this is another task called for in the regular service schedule).

Remove the two bolts securing each cover,

Visually inspect the valve surfaces for breaks, cracks, or dead bugs. Then re-install the covers.

Reassemble the Rest

Push down firmly on the spark plug coils, and you can feel the connection snap into place.

Remembering that ground lug that was part of the wiring harness,

we re-attach the lug to the bolt where it was before.

Replace the vacuum assembly

and all the other hoses and connectors.

Replace the radiator, coolant, carburetors, air box, gas tank, and fairings, and we’re done. After putting the carbs back, but before reinstalling the gas tank, would be a good time to balance and synchronize the carburetors.

what is the proper camshaft cap loosening sequence. the kawasaki manual shows a sequence for tightening. what is the sequence for loosening?

salut, j’ai beaucoup appris avec ces explications simples et concrètes, maintenant je suis assez confiant pour faire le travail moi même, sur ma zx600 merci.

im a new bike technician. im currently in school for just this type work. I googled 05 636 valve specs and I found this blog\tutorial and to be honest I learned a lot from it I read it all and will take the job with confidence and my customer will be greatful do u have any honda f4i blogs?

非常有帮助,谢谢!

Can you explain how you kept timing chain in place and cams wgile retightening cam bolts and plate without it akipping teeth?

Ihad to have my buddy help me

Hi , I just checked my 1999 zx6r valve measurements and they are all with in specs, I brought it to this guy and he supposing did them all, BUT now I notice the intake cam is off by 1 tooth, When I have the exhaust gear set at that line for EX the in mark on the intake gear is on pin number 31, now would that make my valves sound like they have a tap, which might really be a ping? Please help, again all valves are within specs, and I have a what sounds like a tap a rap!

Take your time and make sure the marks on the camshafts are as close as possible. It takes a bit of adjusting and prepare to spend several hours. It should be done at TDC, I only have one line on the sproket and if you look down the spark holes, pistons 1 & 4 should be dead top. When the chain tensioner is out, do not try and adjust the timing with a ratchet to shift it slightly. You will mess up the timing and have to take it all apart again. Keep checking marks as you torque.

UPDATE: I had to reset the cam timing marks again and everything was perfect. I followed the torque sequence per the Kawi shop manual and did it in 3 phases (hand tight, 1st torque value roughly 4 inches and 2nd of 8.5 inches. After doing this again I noticed the timing mark on the crankcase shifted. I left it off-mark. I put the chain tensioner in per the manual, tightened it up and cranked the crankcase 2 times to get back to the timing mark again. Perfect. The tensioner will correct the gap. Good luck.

very helpful Thanks.

Hey thanks for the write-up! I thought I’d share something I found… I’ve got a ’96 ZX-6R, and just finished doing my valves for the first time since owning the bike. My Clymer manual has the math wrong, it’s saying that as the valve recesses, you need a larger shim. It even has an example where they start with a smaller shim, the feeler blade gap was under spec, so they installed an even bigger shim. I thought that just didn’t make any sense so I Googled it and came across this post. Thank you sir!

Sometimes you do need thicker shims as the valve stem shortens under cyclical compressive shock loads – normal operaton.

You’re the man!

Thanks a bunch- (My bike thanks you too)

THE RECEESES IN THE CYL. HEAD AT THE END OF THE CAM SHAFT ARE FOR LINE BORING THE HEAD AND THE CAM PLATE I.E. MACHINING PROCESSES.

Nice Tutorial!

One detail I need to know is the correct sequence for tightening the cam cap bolts. Nothing in my shop manual specifies any tightening sequence.

Cheers!

too complicated for me lol but excellent posts man keep em coming!

Well take a look at how the camshafts sit in the head. Next we have the cam tower. These parts are match machined heas one when torqued in place (this is why torque values are important)

Those “recesses” allow the cam journal to be machined and honed. You cannot just swap these parts from motor to motor as each one will be different. IF you break the tower you will need a new head. Make sure you snug them up very slowly and in the correct sequence&|60;:)

First time I’ve attempted a job like this on my Ninja and thanks to your post its all gone really smoothly. Brilliant job – many thanks

Thank you so much!

hello.

I have had my valve clearances done, 8 needed doing. carbs balanced, and still my engine is making that (diesel) noise, hot or cold. So now Ive got a tensioner (not ape) O.E one. After looking at your piece above, I feel very confident about doing my manual cct, as all other work has been done by my local dealer who says my cct is the last thing you check after the other work??????

A big thank you for the time and effort you put into this.

Cheers.

brilliant post. cheers.

key points for this procedure again inch pounds on the torque wrench read the markings carefully.

And when using the feeler gauges and micrometer the touch is very key. You want there to be slight drag, not so much you cant get the feeler in or can’t pull it out without dugging but not so loose it just slides free you want just the right amount of resistance

And when you all re-shimed and have the cams back on using the bolt spin the engine all the way around 2 or 3 times before recheckin the tolerance

Thanks for the painstaking job of photographing all of your steps. I have a 94 ZX6 that I plan on adjusting. I’m contemplating waiting until the end of the season, but not knowing if it’s ever been checked by previous owners, I not sure if I should wait.